May / June 2009

Overhaul of Traction Motor Blower #1 At the end of March two Traction Motor Blower (TMB) motors and two exhausters were transported from Bury to my home workshop (garage) for overhaul when I have days off work.. This is the story of the overhaul of 1 st TMB motor. A start was made on stripping TMB1 down the week after arrival, and a start made on cleaning/needle gunning/drelling the outer casing and fan. Upon testing during the strip down it was found that the field coils resistances were hard down. Attempts were made to dry them out with an industrial fan heater, but to no avail. Eventually it was decided to completely strip the coils out of the casing and get them in an oven to see if this would dry them out better. The coils and inter-poles were dried out a few at a time in the oven at home, disguising the smell afterwards from the missus was no fun though! Whilst the coils were out opportunity was taken to completely strip out the carcass of old varnish etc and paint with anti-corrosive primer. Then the dried out field coils were refitted, and with all the links between them back on, the resistance reading had risen to way beyond expected. Anti tracking varnish was then applied to the field coils and allowed to dry. Over the coming weeks various other items were cleaned up such as bearings and others drelled and anti-tracking varnish applied. A few weeks ago during one day, we decided to rebuild TMB1 and get it running. The front plate was cleaned up and anti tracked, and all the brush-boxes cleaned up on the wire-wheel. This was then refitted to the carcass, and then the commutator inserted, then the back plate was refitted and all bolted up. The brushes were refitted and it took some fiddling to get the motor to spin freely by hand so the bearings were seated right. Once spinning freely we attached some jump leads to my cars battery and then the motor and she burst into life with no apparent grief. A relief and an achievement! The following days saw the motor get painted up and various covers were drelled and painted up and refitted. I transported the air duct snail for the motor from Bury, which was cleaned up and painted by other members on working weekends, and this has now been refitted. So this TMB motor is now complete and awaits fitting to D8233, it is earmarked to go in No1 nose-end where the ducting mods are currently taking place. A big thanks to Carl Holt with his help and advise during the overhaul, my round for the breakfasts next Carl! Chris Baily

|

|

| Above : Removal of TMB from the loco. © C15PS |

|

| Above : After needle gunning and drelling. © C15PS |

|

| Above : The removed commutator. © C15PS |

|

| Above : Field coils and interpoles baking in the oven (dont tell the wife!) © C15PS |

|

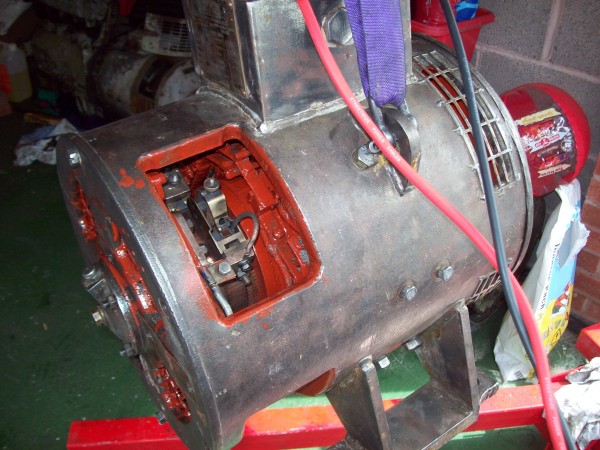

Above :

Rebuilt and now with a coat of anti-tracking varnish. © C15PS |

|

Above :

Successful testing of the machine powered by a car battery. © C15PS |

|

| Above : Rebuilt TMB with the snail duct attached and ready to refit to the loco © C15PS |

Fancy Getting Involved? click on the You Can Help page