Saturday 21st July Today work continued on the cooler group rebuild, the Gloucester lads were in

attendance for the day and their first task was to adjust the left hand

cooler group tank so that radiator elements fitted properly to both top and

bottom rails. With this done, they then set about fitting one of the bottom

tank coolant pipes and the bottom oil tank balance pipe. One of the lads

continued the undercoating of No1 end nose compartment in readiness for

gloss being applied. More cooler group water pipework was cleaned up and

given a coat of primer. The opportunity was also taken this day to remove

the covers between the power unit and main generator, this is so we could

ascertain how the pair fit together in readiness for splitting them off

later this year.

Sunday 22nd July Only a handful of members present today. More cooler group components were

cleaned up and given the paint treatment today, these mainly being the fan

drive shafts and the water pipes were given a coat of undercoat. With the

undercoat now dry in No1 end nose compartment, the roof and walls were given

a coat of grey gloss, it just needs the floor catching up now for this compartment to be ready for parts to be fitted back in.

Monday 23rd July Three of us were away from work for the next few days, so the opportunity

for a mid week work session was taken. Today we managed to test the oil

thermostat valve (or Ted valve as its now become! short for Teddington valve

who manufactured it) This involved stripping the Ted down, the wax element

was then placed in a pan (sorry Linda!) of hot water and heated up even more,

this was to check the temperature it started to open and was fully open

using a thermometer. It was then rebuilt and tested again, to ensure that

the valve was moving ok and nothing stuck either shut or open. Once done, we

headed off down to the coach to apply gloss to the water pipes and prep and

prime the Ted valve.

Tuesday 24th July Three of us present again, we headed off down the coach and first job was to

apply gloss to the Ted valve and fan drive shafts. We then set about fitting

two pieces of conduit on the left hand side floor of the cooler group that

had been missed previously, but in order to do this properly two long runs of

conduit needed removing from the engine compartment, so out came the

wire brushes, WD40 and brute force! Gaskets were made for the top water pipes

and oil pipes ready for refitting.

A mega was borrowed from Castlecroft so

we could get a general idea what condition the electrical left on D8233 were

in after 20 years being stood. The results were surprising, the main

generator and aux generator showed a good reading considering the amount of

time they have been stood idle, the exciter's reading was even better, and

the compressor motor's reading was as if it was brand new! The two

exhausters reading were very low compared to the rest, but as all the motors

on D8233 will be looked at and given a overhaul before use they shouldn't

pose a problem.

The top water pipes, were then refitted along with some of the top oil pipes

in the cooler group then we all called it a day!

Wednesday 25th of July

Three became one today, as two of us had to return to the daily grind of home life

and work! However Jason Lovell forged ahead with cooler group rebuild a

short note of what he did is below:

Had a bit of a general tidy up in the support coach.

Then spent the rest of the day sorting out the sales stand stock and reboxing everything.

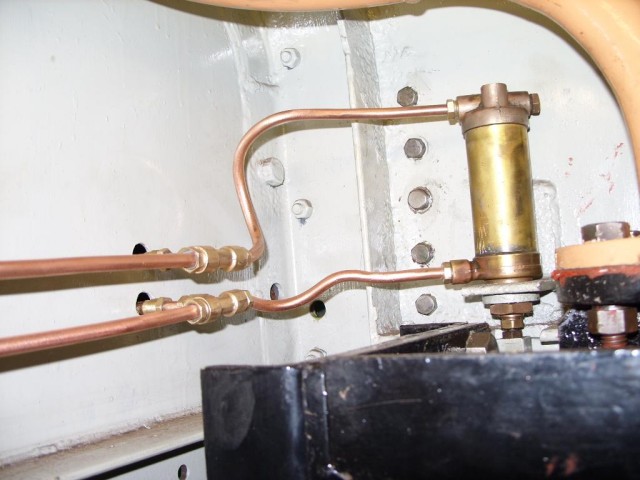

Thursday 26th July 2007 I made some additional gaskets for the Ted Valve and then fitted the valve to the base mounting pipe. Took the Ted valve assembly into the cooler group and fitted to the base plate on the floor & pipe flange to the bulkhead.

I fitted the two outlet pipes to the valve, sealing the joints with the red gastight sealant.

The Ermeto joints were then loosened to help locate the oil pipe flanges on the top radiator tanks. Once located, sealed & bolted down tight the L/H top oil pipe flange mounting. The R/H top oil pipe flange and then tightened all Ermeto joints as much as possible.

Friday 27th July 2007 Drelled radiator shutter air pipes they came out bright copper/brass finish, decided to fit unpainted. In the cooler group the shutter air pipes, bulkhead clamps were fitted and all joints tightened. Various cooler group components were located and prepared for fitting in the next working weekend. These included the large pipe clamp that fits the top of the oil bypass pipe, the fan drive couplings, filter drip tray drain pipe, fan brace bars and hanging brackets. Over the seven days a lot was achieved, the cooler group is very nearly

finished, the radiator fan itself is now away for repair and should be back

at Bury in the not to distant future, everything left to rebuild in the

compartment is fan related (bar the elements) we are hoping that by September

the cooler group will be done and we can move onto the engine compartment

and No1 compartment.

Some photos of the work are below. |